SERVICES

OUR SERVICES

Identify & Prioritize Printable Spare Parts

We begin by working closely with your engineering, maintenance, and procurement teams to:

Map out your current spare parts inventory and usage trends

Identify high-cost, high-risk, or long-lead-time components

Evaluate technical feasibility and business case for 3D printing

Our goal is to uncover where additive manufacturing delivers real, measurable ROI — whether through cost savings, lead-time reduction, or increased part availability.

Redesign & Validate Each Part

We don’t just convert parts — we optimize them.

Our design engineers assess each part’s geometry, load paths, tolerances, and materials. Using advanced CAD tools, we:

Re-engineer parts for additive manufacturing (DfAM)

Enhance performance, reduce weight, or consolidate assemblies

Run simulations and stress tests for functional validation

Each part is tested to meet its real-world demands — not just in theory, but in practice.

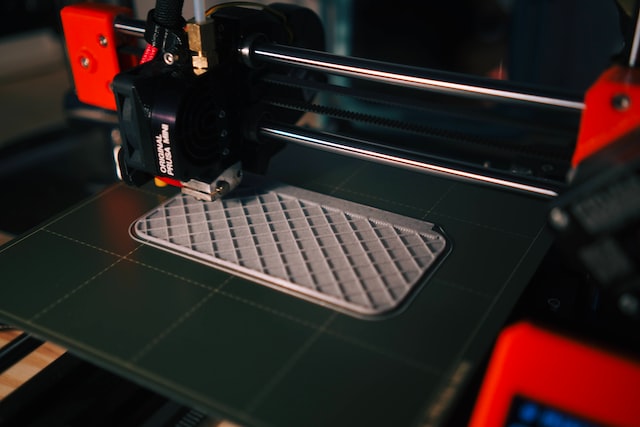

Print Setup & Certification

For every validated part, we define a complete print package, including:

Printer model(s) and compatible material types

Layer height, infill, orientation, and post-processing requirements

Estimated print time and cost-per-part

We also ensure all parts are backed by digital traceability, documented settings, and quality benchmarks — enabling repeatable, certifiable production every time.

Production with Strict Quality Control

Our batch production process is tailored for industrial-grade performance:

Every print follows validated, part-specific settings

Materials are verified for mechanical, thermal, and chemical compatibility

Inspections and process monitoring ensure consistency across batches

From a single part to full-scale production, our focus remains the same: precision, reliability, and repeatability.

Performance Tracking & Savings Attribution

Post-deployment, we continuously monitor performance to help you measure what matters:

In-field performance and maintenance data

Lead time and cost savings per part

Cumulative impact on operational uptime

This data isn’t just for reporting — it feeds into a cycle of continuous improvement, allowing us to refine designs, processes, and strategies over time.